At Ideal Aerosmith, we help clients break free from complex challenges. Known for our motion testing hardware and software, our true strength lies in our people. Our team of problem solvers asks the right questions, uncovers opportunities, and pursues solutions with relentless dedication — always focused on our customers’ success.

Learn MoreOur manufacturing team delivers precision at every level from build-to-print to contract manufacturing services including cable, fixture, and mechanical assemblies. With IPC-A-610-certified inspection personnel, we ensure quality, reliability, and performance in every product we deliver.

01Ideal Aerosmith’s Inertial Test Laboratory (ITL) offers testing-as-a-service for short-term, periodic, or custom motion simulation, without the cost of ownership. We help manufacturers and integrators accelerate product development with immediate access to ITL equipment.

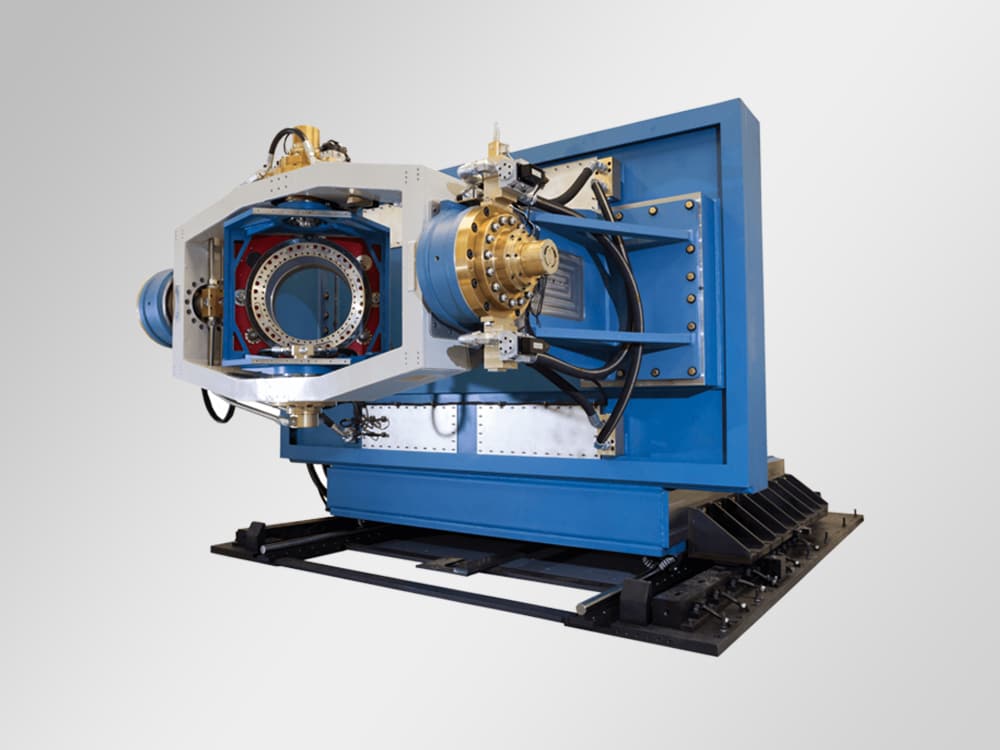

02At Ideal Aerosmith, our motion systems include flight motion simulation systems, single and multi axis rate table systems, centrifuges, and motion control systems. Our systems are used for inertial testing across a wide range of operational environments and applications.

03Our engineering services include electrical, mechanical, and software engineering. This also encompasses electronic and electro-mechanical test requirements capture, design, fabrication, development of low- and high-level test software, and full implementation support.

04This encompasses the development and application of unmanned systems, accelerated DOD technical development and prototyping efforts, systems engineering and technical assistance (SETA) support, and the rapid design and manufacturing of solutions at both speed and scale.

05