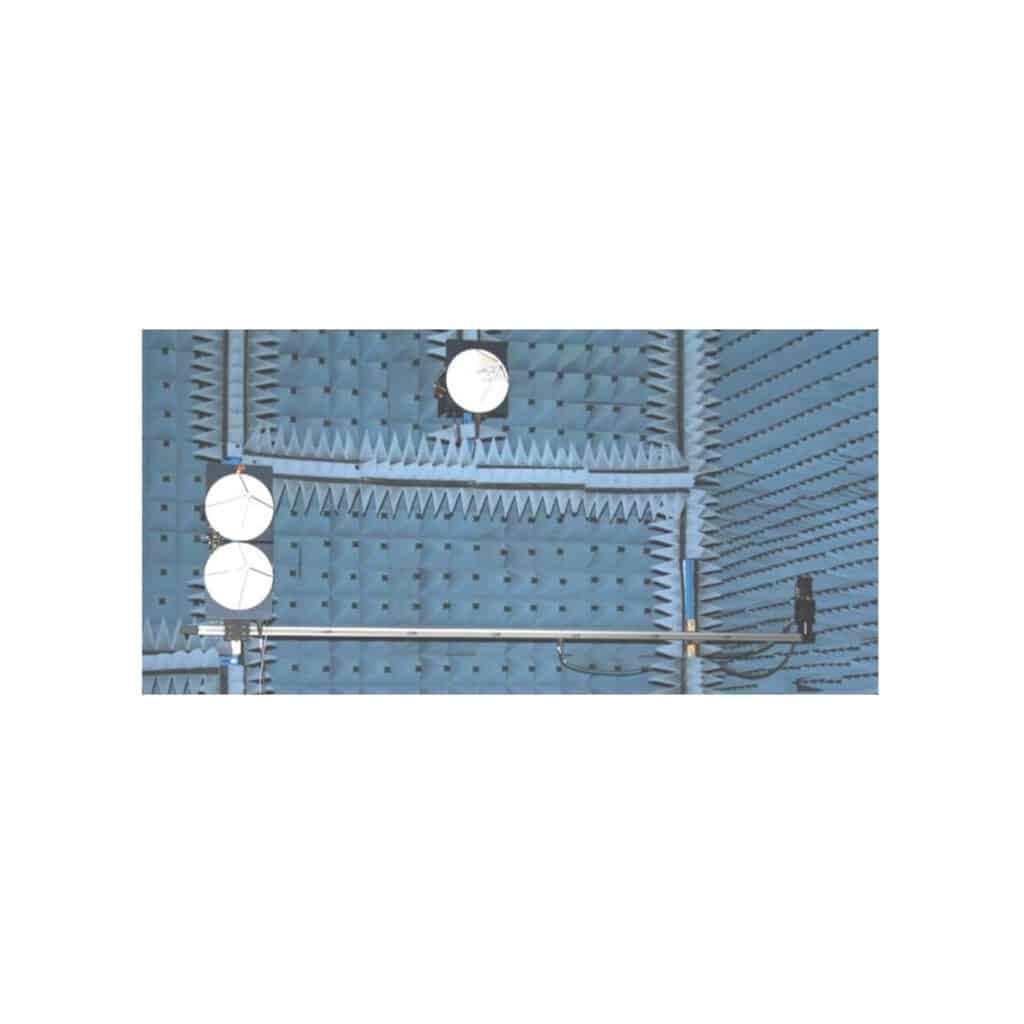

Ideal Aerosmith manufactures high-precision and high-dynamic three axis and five axis Flight Motion Simulator (FMS) systems for Hardware-In-The-Loop (HWIL) development and production testing of missile guidance and seeker packages. These motion simulators are configured to test and evaluate RF, IR, and laser seekers by providing a synthetic dynamic environment in the laboratory or in an RF anechoic chamber. We are uniquely qualified to design, fabricate, install, and commission:

Ideal Aerosmith’s FMS/HWIL systems are configured with the AERO4000™ Digital Motion Controller. This controller is configured to accommodate “Reflective Memory Interface” (RMI) communication cards that support the high-speed data transfer required by HWIL simulations.

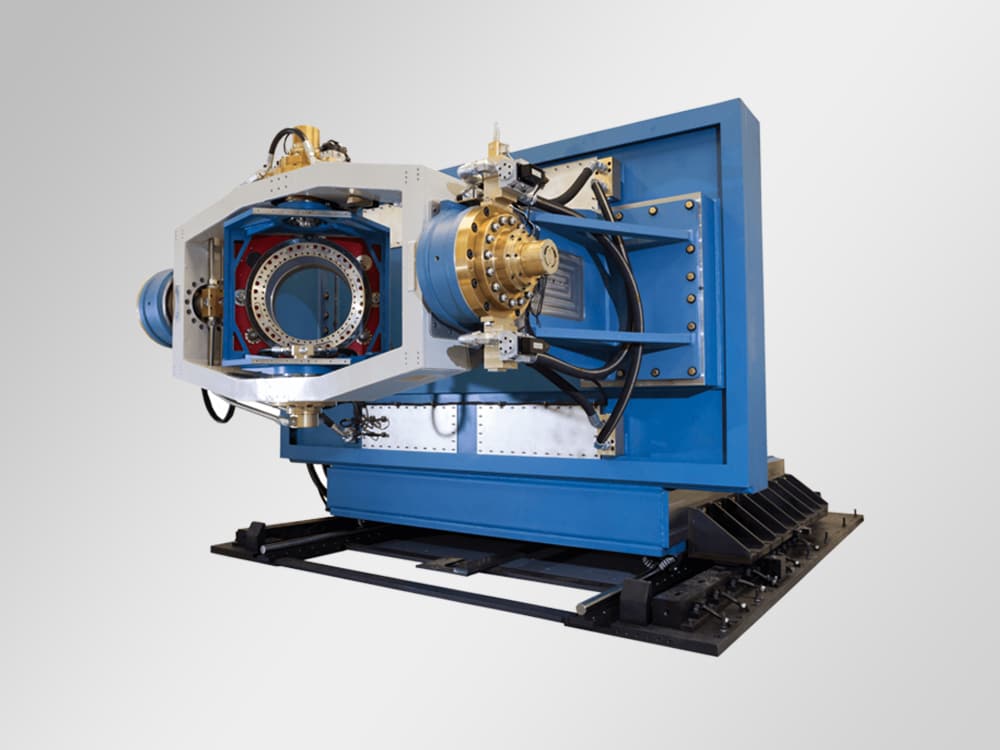

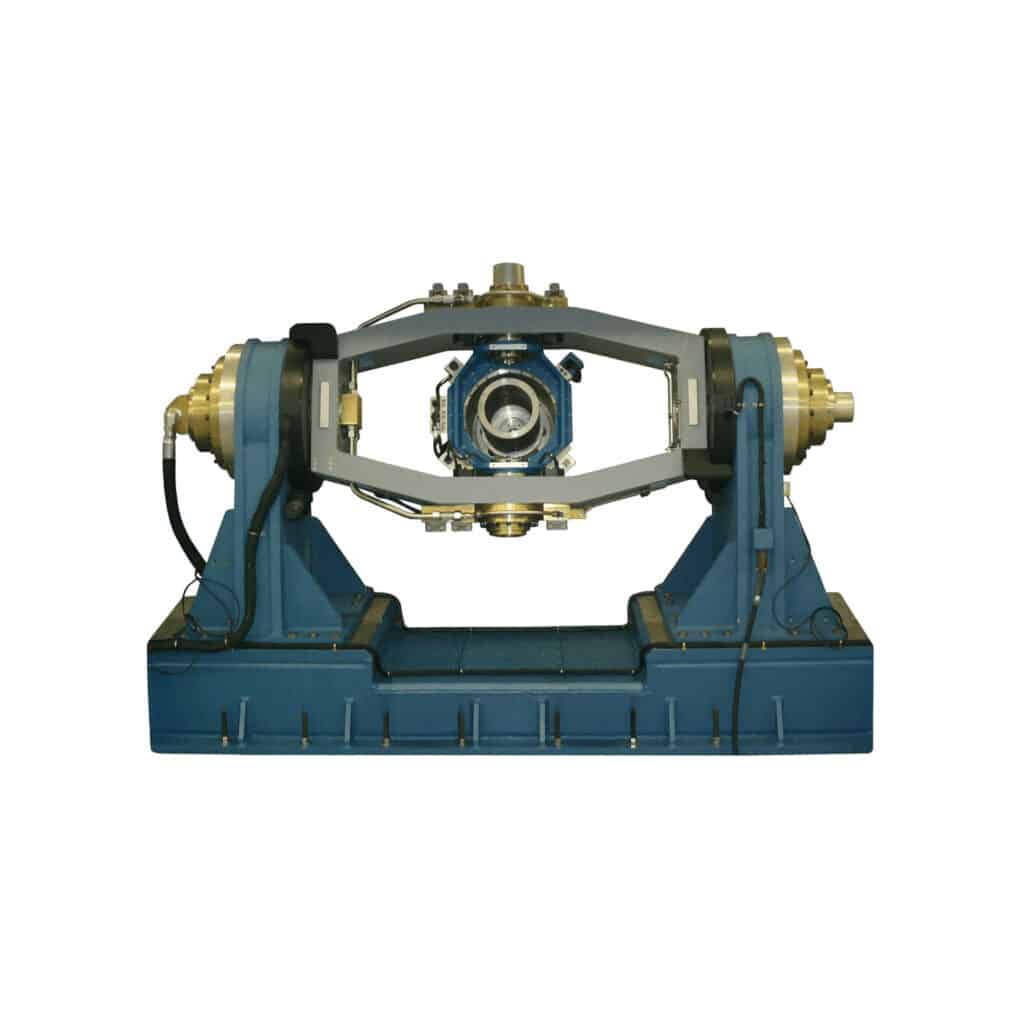

These systems feature high-torque, direct-drive DC brushless motors that provide a very attractive torque-to-weight ratio when compared to electric brush-type DC drive motors. Our motion simulators are configured to test and evaluate inertial guidance electronics, munitions, and a variety of sensors in the laboratory environment or within an RF anechoic chamber.

Ideal Aerosmith is uniquely qualified to design, fabricate, integrate, test, install, and commission a hydraulic or electric actuated Flight Motion Simulator required for the successful execution of major infrared, laser, or RF seeker system development programs. Ideal has an excellent reputation for designing and manufacturing “Hardware-In-The-Loop” (HWIL) test systems and has demonstrated the dedication to support those systems to meet our customers’ highest expectations.

Our three axis and five axis systems feature high-torque hydraulic actuators that provide a very attractive “torque to weight ratio” when compared to electric drive motors with similar torque output. Ideal Aerosmith hydraulic Flight Motion Simulators are controlled by the AERO4000™ Digital Motion Controller. Our AERO4000™ Controller is built upon commercial off-the-shelf (COTS) hardware and software platforms to minimize cost and delivery schedules. The AERO4000™ is a robust controller designed to provide high-dynamic HWIL missile seeker flight simulations.

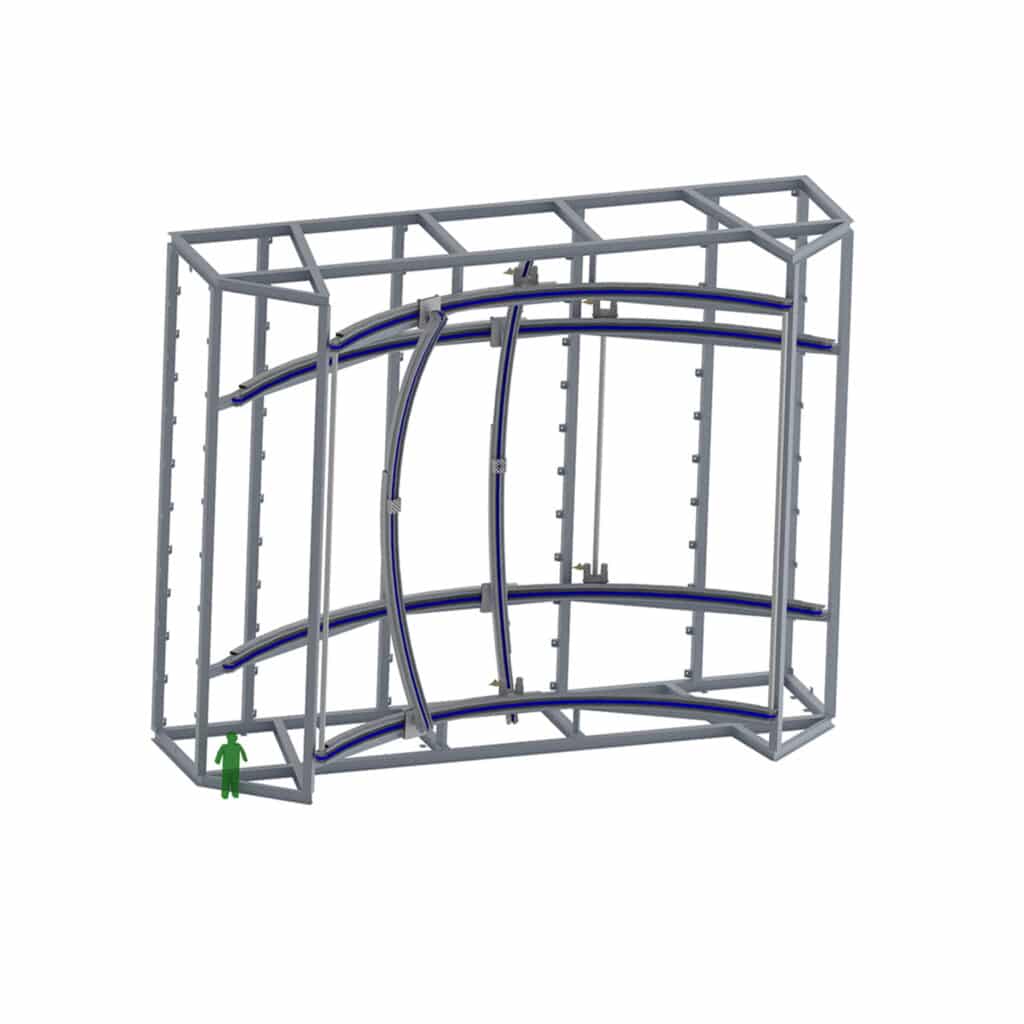

Ideal Aerosmith specializes in the design and manufacture of high-performance TMS systems for Hardware-In-The-Loop (HWIL) testing of missile seekers (IR, laser, or RF), guided munitions, and inertial guidance systems. TMS system solutions may consist of various configurations such as a 2X gimbal (i.e., rotary) system, a linear X-Y system, a curvilinear X-Y system, or a dual X-Y system. Any of the Ideal TMS systems are compatible with the Ideal Aerosmith three axis FMS built by the former Carco Electronics or Contraves companies.

Ideal Aerosmith TMS systems are controlled by the AERO4000™ Digital Motion Controller. Our AERO4000™ Controller is built upon commercial off-the-shelf (COTS) hardware and software platforms to minimize cost and delivery schedules. The AERO4000™ is a robust controller designed to provide high-dynamic target motion for HWIL missile seeker flight simulations.

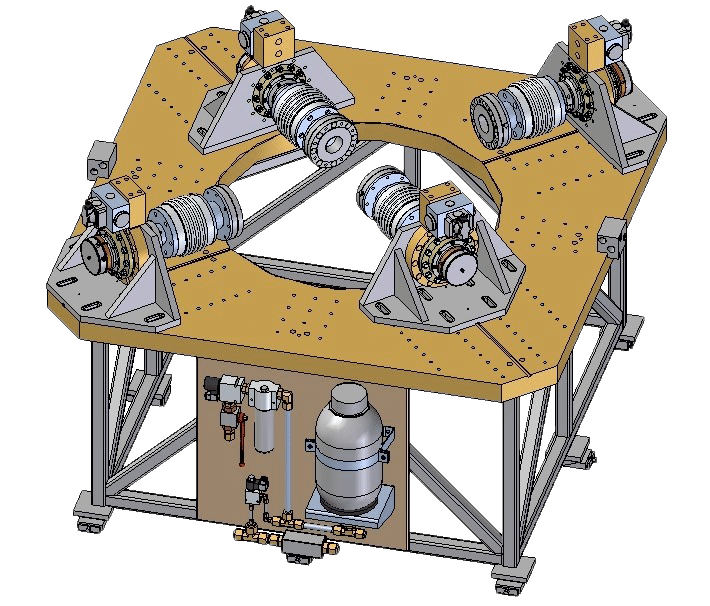

The Aeroload Simulation System — sometimes referred to as a “fin loader” — is a general purpose test instrument that may produce a wide range of rotary position motions and/or active range dynamic torque to simulate aerodynamic loads applied to control surfaces such as fins on missile systems during flight.

Many customers use this equipment in conjunction with a multi axis Flight Motion Simulator (FMS) to complete the Hardware-In-The-Loop test suite for guidance and navigation programs.