High-Performance SPI Communication Through Slip Rings

Featuring Marius Gheorghe, PhD, Chief Engineer – System Solutions

The Challenge

Inertial sensor manufacturers that test micro-electro-mechanical systems (MEMS) with Serial Peripheral Interface (SPI) links face significant challenges. SPI was introduced in the early 1980s for short-range, board-level communication, and it became popular for its high data rates and full-duplex capability. However, those strengths turn into limitations when the interface must operate over distances greater than a few tenths of centimeters.

In Inertial MEMS testing, sensors are mounted on a tabletop, while the data-acquisition system controlling them is typically located at the base of the rate or positioning table – often in the 10-meter range away. To bridge this gap, some manufacturers rely on rate and positioning tables with external tabletops (sacrificing workspace, dynamics, and cost efficiency), reduce communication speeds (undesirable when many devices must be tested in parallel), or use expensive FPGA-based clock-delay solutions that require painstaking re-tuning whenever the setup changes.

The Solution

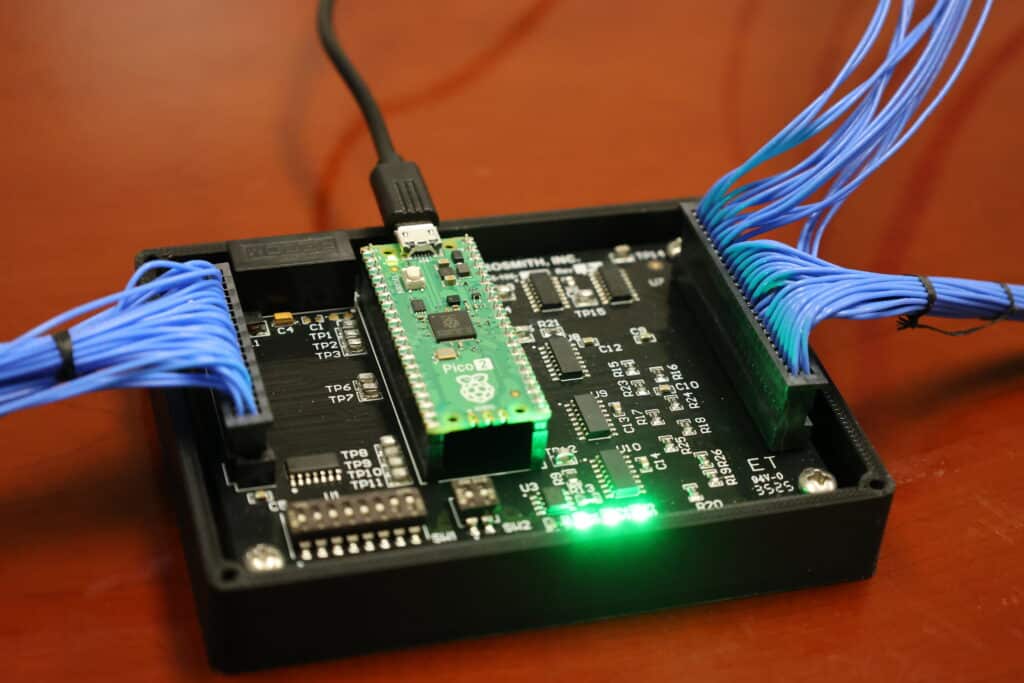

Ideal Aerosmith Inc. has developed a high-performance solution for extending SPI communication through the slip rings of rate and positioning tables. The system consists of a base electronics module and a tabletop electronics module that together preserve SPI timing integrity over long distances and through slip rings, without sacrificing speed.

Testing at Ideal Aerosmith’s Inertial Test Laboratory in Phoenix, Arizona demonstrated sustained data rates of 22.5 MHz on a three-axis rate and positioning table and 30 MHz on a single-axis rate table. These speeds comfortably meet the needs of modern inertial sensors, most of which specify 10 MHz operation. Only the highest-end devices are capable of 24 MHz transfers.

The Outcomes

The solution also supports multi-device testing using built-in chip-select lines, which can also be configured as multiplexer address lines. Small-scale projects can test up to eight devices with no additional hardware, while large-scale systems can handle up to 128 devices with the addition of external multiplexing circuitry. In all cases, the system streamlines testing, preserves performance, reduces cost and complexity, and can be adapted to existing rate and positioning tables.