Featuring Marius Gheorghe, PhD, Chief Engineer – System Solutions and Co-author David Boura, Sr. Systems Engineer

Cascaded Thermal Control

The Challenge

There’s no secret that testing time is money, and one of the biggest contributors to long test cycles is the thermal stabilization of the unit under test (UUT).

Inside thermal chambers, UUTs are heated or cooled by streams of hot or cold air. The rate at which the UUT temperature changes depends largely on the temperature difference between the UUT and the chamber air.

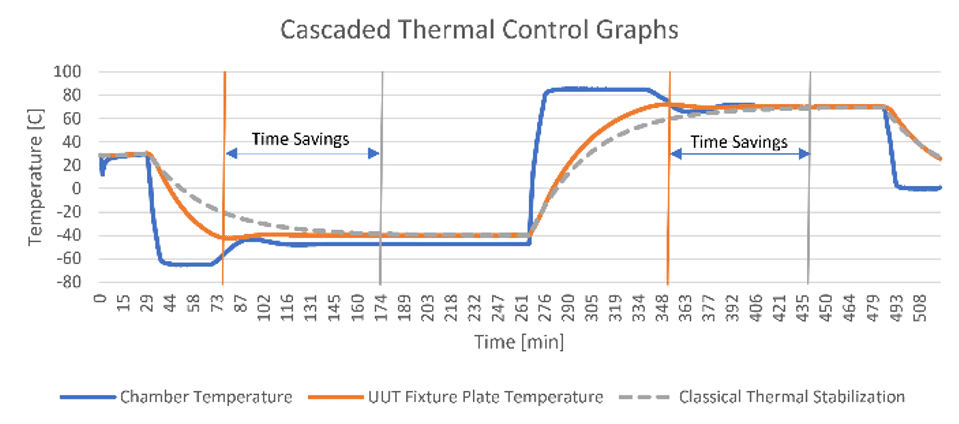

In traditional thermal-chamber control schemes, reaching the target UUT temperature can take a long time. As the UUT approaches the chamber temperature, the driving thermal gradient shrinks, causing the UUT temperature to creep toward the target asymptotically. Most of the total test time is spent on those final few degrees.

One solution to speed this up is to overdrive the air temperature. However, without careful control, this can cause the UUT to overshoot the target.

The Solution

The cascaded, dual-loop temperature control monitors both the temperature of the air in the thermal chamber and that of the baseplate on which the UUT is mounted. This allows the thermal controller to use a much higher or lower temperature initially to speed up the thermal transfer to the UUT, while making sure that the UUT temperature does not overshoot the desired target. This is achieved by monitoring the temperature of the baseplate.

While the UUT temperature still follows an asymptotic curve—physics hasn’t changed—the dual-loop architecture accelerates the process by creating a much steeper initial slope (see Figure 1).

The Outcomes

This cascaded approach has been deployed in multiple projects with substantial reductions in test time. The initial investment of adding baseplate thermal sensors and a capable controller is quickly offset by the recurring savings achieved through faster, more efficient testing.